-

Testing The Power, Rotational Speed, Consumption, Torque And etc For Electric Motor.

-

Not Only Testing The Adhesion of Electroplating Parts, But Also Inspecting The Corrosion Resistance And The Weather Resisting Property.

-

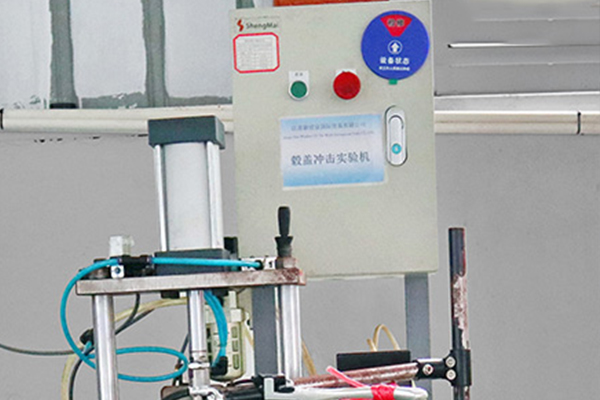

The Brake System Continuously Broken Under The Simulation Condition At High Speed State, To Test The Impact of Structural Strength, Shock & Fatigue Resistance For The Brake Hubcaps.

-

The Main Applications & Functions To Electric Motorcycle Manufacturing: Not Only Testing The Adhesion of Electroplating Parts, But Also Inspecting The Corrosion Resistance And The Weather Resisting Property.

-

The Main Applications & Functions To Electric Motorcycle Manufacturing: Auto Detect Integrities For The Parts & Spare Parts Assy. Under The Different Temperatures And Humidity States(The Adjusted Temperatures Range: –40°C~+150°C)

-

Measuring Battery's Electric Power Capacitance And Its Charging-discharging Lasting Service Life, Testing The Battery's Self-repairing Capability At The Under Voltage States.

-

The Main Applications & Functions To Electric Motorcycle Manufacturing: Carrying Out Whole Automatic Welding Processes To Metal Structures By The Programming Way.

-

The Main Applications & Functions To Electric Motorcycle Manufacturing: With Extruder Process Function At 0.3/0.5/0.7 Three Kinds Specifications For The Wiring Harness Cables.